Editor’s Note: In a three-part series concluding today, Treesource is exploring the potential roles of forests and wood products in addressing the global climate crisis.

Part 1 (Read it here): How can we use more wood, a renewable, biodegradable carbon sink, while also storing more carbon in forests across the U.S. and the world?

Part 2 (Read it here): What incentives and regulations are needed for landowners, forest stewards, corporations, governments and NGOs to change their practices and thereby make carbon storage a top priority?

Part 3 (Today) A look ahead to 2050. What could a more sustainable society look like, if forests and wood products were utilized in new and more effective ways?

Imagine stepping out of a time machine in June 2050 — and finding yourself atop a 28-story, mass-timber building perched amidst a forest of high-rises on Chicago’s South Side.

Except for the Windy City’s rather brisk breeze, you find the panorama provocative, remarkable, intriguing: You can see many of the city’s neighborhoods, distinguished by crowns of trees planted in the 2020s and 2030s. Living roofs and skywalks connect buildings while Chicagoans picnic under the greenery and walk their dogs. Cyclists pedal their ways to work or home, or maybe shopping.

The mayor greets you, as do the governor and the president standing next to him. They have come to celebrate a long-hoped-for achievement: This year, finally, the world has recorded a decrease in atmospheric CO2. Such celebrations are under way worldwide.

In a rooftop address, the president describes the series of actions that delivered this hoped-for result. In addition to remaking the energy production system, she highlights other climate-saving projects that prudently invested in forests and their products:

- The rapid increase in the number of mass timber buildings, bridges and other structures, all resulting from sustainably grown forests that, together, have reduced the amount of energy needed to create this newly built environment.

- These new forests were planted to replace the deforestation of the 20th Century and the early 21st Century. The global expansion forested acreage, now pull CO2 out of the atmosphere and store it every day — and will continue to do so, while providing a sustainable supply of wood society’s needs.

- The world’s forest owners have received regular, reliable payments for carbon capture and storage. In turn, this “new” revenue enabled them to adopt management practices that store even more carbon.

- Many of these forests are also managed to restore biological diversity — while providing more wood for human use. The most biologically diverse forests have been reserved to maintain these values and purposes.

- In addition, new biochar production — achieved through new technologies of biomass-energy carbon capture—has led directly to the storage of gigatons of carbon-dioxide equivalents.

These “new” gigatons of bio-carbon end up being used in:

- Soils of forests and farm fields, to make them more productive.

- Feedstocks for use in concrete, bioplastics and green steel.

- Higher Quality of Water resulting from better management of urban and municipal stormwater.

- Cellulosic Nanoparticles that have revolutionized materials used by the aeronautical and automobile industries. These nanoparticles dramatically reduce the weight of aircraft, trucks, buses and cars while making them stronger — and while creating “green” tires that get better mileage AND store carbon.

- Wood-Fiber Insulation. Rigid board, batt and blown materials have replaced extruded polystyrene and other fossil-intensive materials. Wood-fiber insulation is also less flammable, without noxious “off-gassing.” Consequently, wood-fiber insulation is safer AND it stores carbon for long periods of time, thereby reducing a building’s heating and cooling needs.

- Glass made from cellulose, which has replaced traditional glass, saving huge quantities of energy in the manufacturing process and increasing the insulation quality, further conserving energy.

- Windmills made of wood, which reduces the embodied energy.

Okay, Time Traveler. Now take a deep breath, relax and let yourself snap back to 2022.

The roster of wood-related achievements that you’ve just encountered was NOT fantasy. Certainly not!

All the requisite technologies exist today, although many have not yet penetrated consumer markets. There’s no guarantee that these technologies will reach consumers. However, they are the work of motivated partners across the vital economic sectors of government, industry, financial investors, academic researchers and non-governmental organizations — all intent on producing a sustainable future.

As Michael Goergen, vice president of the U.S. Endowment for Forests and Communities, observes: “To bring new products into the market requires work on … perception, legal, regulatory, financial and other aspects. … It needs to do more than just help reduce carbon. It has to save money and improve performance.”

Consider the stunning expansion in the use of mass timber just since 2014: From single-digit annual growth to more than 1,200 commercial and multi-family buildings, according to Brian Brashaw, assistant director of the U.S. Forest Service’s wood innovation program.

Brashaw believes more than 17,000 of the steel and concrete buildings currently constructed each year could instead be made from wood.

So far, there are about a dozen U.S. and Canadian manufacturers of mass timber building materials. Europe also supplies North America.

The rapid increase in mass-timber structures over the past seven years has required coordinated efforts — to change building codes, to provide testing that’s capable of verifying the wood’s strength, and to test its durability during fires, or replications of stress and movement during earthquakes.

To achieve the successes that mass-timber buildings have experienced in such a short time, partnerships were needed among NGOs, universities, industry associations, investors and governments at all levels.

The results of more than a decade of research and development of cellulosic nanoparticles and near nano-sized particles could now be on the verge of growth comparable to that experienced by mass timber.

Three product lines have the potential to achieve the rapid growth that will require investments in new production facilities and the launch of other products, said Michael Goergen, vice president of the U.S. Endowment for Forests and Communities.

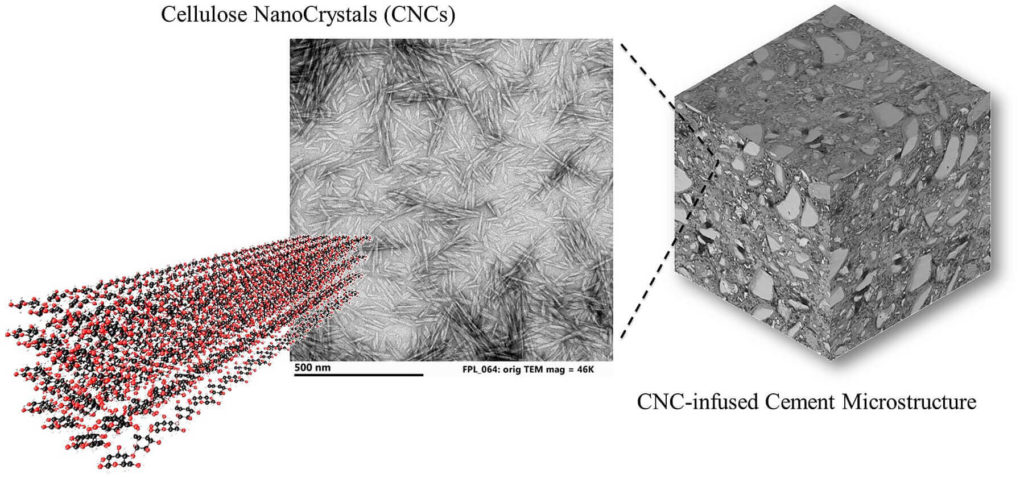

No. 1: Nanocrystals as an additive to concrete.

If concrete were a country, it would be the third largest emitter of greenhouse gases on the planet. While a phenomenal construction material, though, it has an Achilles heel – its massive carbon footprint. Enter nanocrystals. A small amount of these particles added to concrete can reduce its carbon emissions by 15 percent to 50 percent, depending upon a variety of factors.

“One gallon of nano mixed with nine gallons of water, added to an eight-ton concrete truck” can achieve these reductions, Goergen said. That’s because nanocrystals enhance water dispersion throughout the concrete mix.

He explained: “You know how when you make pancakes, you always end up with little pockets of dry mix at the point when you pour the batter into the pan? Well, the addition of cellulosic nanoparticles to the mix keeps the concrete from having pockets of dry cement, thereby reducing the amount of cement needed, which is the primary source of carbon emissions.”

Not only that, but the use of nanoparticles reduces the wear and tear on concrete equipment used in construction and it can be pumped further. The first bridge built with this enhanced concrete is near Yreka, California.

Now the California Department of Transportation is working with researchers on nano-concrete’s use in pavement and other applications to reduce the state’s overall greenhouse gas emissions.

The Federal Highway Administration is watching the results and the potential for incorporating this new technology into projects funded by the 2021 Infrastructure Bill.

Separate research has shown the addition of biochar to concrete can also reduce carbon emissions and strengthen the “end product.” The potential synergy between these two additives has yet to be tested.

No. 2: Wood nano-particles also could help reverse the bleaching of coral reefs. Chemicals used to create some sunscreens has been tied to the bleaching of coral, leading to bans on such (but not all) sun blockers. Researchers have discovered that nanocrystals can be formulated and used as a sunscreen or added to cosmetics to create a clear SPF 15 sunscreen without the deleterious effects on coral.

A third major use of cellulosic nanocrystals is in tire manufacturing. The use of renewable wood cellulose in place of petrochemical additives could drastically change the carbon footprint of tires. Researchers have learned the addition also reduces the rolling resistance and weight of tires, thereby increasing the vehicle’s miles per gallon – or per charge. Goergen expects the “wooden tires” will soon be used in high-performance markets like Formula One and Tour de France.

Other opportunities for carbon capture and storage involve the use of biochar in a whole suite of products. Biochar can enhance agriculture and forest soil productivity by adding carbon to hold more moisture and nutrients in the soil. It can help reclaim mining sites, and can be used in water filtration systems and in the manufacture of bioplastics. Each process, in turn, creates renewable energy – called Biomass Energy Carbon Capture and Storage or BECCS.

Cindi West, director of the U.S. Forest Service’s Forest Products Laboratory, hailed biochar’s potential. “The Infrastructure Bill has funding to clean up old mine pollution sites across the country, and biochar can be a big part of that effort. The phenomenal co-benefit is that the captured carbon is stored for many centuries, if not 1,000-plus years, from the branches, tops and unused parts of the trees, which otherwise is often burned in the forest.”

The International and U.S. Biochar Initiatives held a virtual international conference in early December which focused on the business of biochar.

Biochar is made from any type of biomass, whether wood residues from forest management or sawmilling to agricultural residues like rice and nut hulls or human or animal waste and more. It is converted to primarily carbon through pyrolysis, the heating of the biomass in the absence of oxygen or in a low-oxygen environment.

The gases released are burned, ideally to produce energy and the carbon left behind is very resistant to decay. Therefore, the carbon is stored for many hundreds to 1,000-plus years.

Biochar is seen as a potentially powerful way of using plants to extract CO2 from the atmosphere and uses the “waste” stream from forestry and agriculture to store the carbon in a form that is useful for agriculture, land reclamation and as feedstock for bioplastics, filtration systems, etc.

The production of biochar varies from very simple and cheap, albeit inefficient, systems to sophisticated heat and power production.

One of the new product lines is thermoplastics made from biochar. In Berlin, Germany, a start-up company called Made of Air is making durable plastic which is 90 percent carbon from biochar combined with a binding agent made from sugar cane. Made of Air is used for building siding, sunglasses and potentially for automobile components.

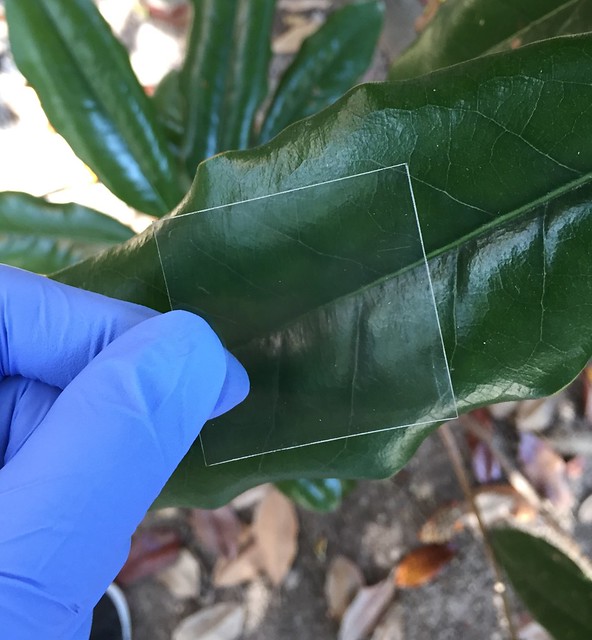

One of the more recent research breakthroughs, West said, came out of the Forest Service’s partnership with the universities of Maryland and Colorado: namely, the manufacture of transparent wood that could replace glass. Compared to glass, the transparent wood is lighter, stronger, and more insulative. Also, it requires less energy to produce.

Now, for a moment, back to the future:

The futuristic image of 2050 South Chicago included a city filled with trees, shrubs and green roofs. Jad Daley, CEO of American Forests, said these urban forests will not only provide excellent shade (which will reduce demand for air-conditioning), but will also capture an estimated 123 million metric tons of carbon per year.

The 2021 Infrastructure Bill provides for the planting of millions more urban trees.

In 2050, real-life residents – not just time travelers – could see the benefits of adaptive forest management that uses ecological, disturbance-based knowledge: Forests that are more resistant and resilient when confronting wildfires, drought, storms, insects and diseases. The U.S. and the rest of the world could be growing more wood, storing more carbon, and maintaining habitat and watersheds that could thereby help buffer the effects of increasingly severe rain and flood events.

Given the increasingly obvious climate changes, combined with those that are coming, Daley, Goergen, Brashaw and West all agree that active management is essential to developing healthy, resilient forests and a diverse wood-products industry—one that can embrace and utilize the whole array of tree sizes.

And when policies that put a price on carbon are implemented, perhaps they can jump-start the investment in and production of these emerging low-carbon technologies. In that way, the future you have just glimpsed, as a Time Traveler reading this article, will become reality.

Leave a Reply